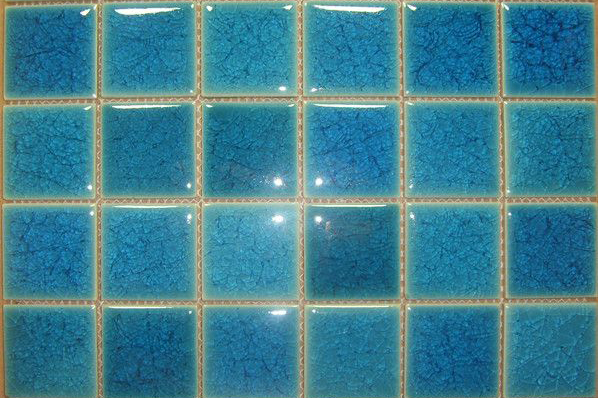

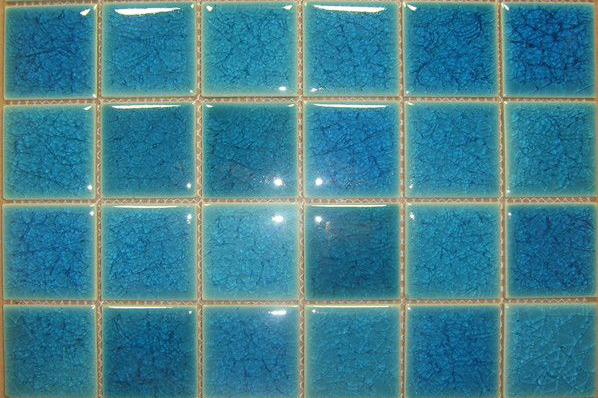

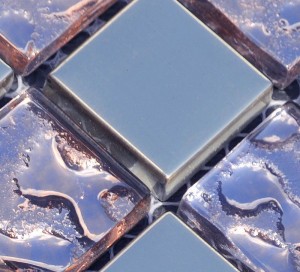

Ho na le likamore tsa ho hlapela tsa khalase tse mebala-bala le mabota a ka ntle

Tlhaloso ea Sehlahisoa

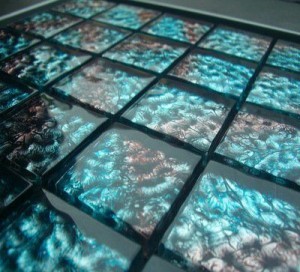

Khalase ea enamele bua ka bokaholimo ba khalase bo sehiloeng ka boholo bo itseng bo koahetsoeng ka 'mala oa fusible glaze, e futhumatsang ho glaze e qhibilihe, e le hore sekhahla sa glaze le khalase li kopane ka tieo, ka ts'ebetso ea sintering, annealing kapa tempering process.khalase ea enamele entsoeng e na le mebala e metle le lipaterone.E na le botsitso bo botle ba lik'hemik'hale le mokhabiso, o loketseng ho haha lithako tsa marako a ka ntle.

Tlhahiso ea khalase ea enamelled e kenyelletsa tlhahiso ea mebala ea glaze, glazing, ho omisa, ho futhumatsa, ho tima kapa ho koala, ho pholisa le mekhoa e meng.

Ho na le lisebelisoa tse peli tsa motheo tsa tlhahiso ea khalase ea glaze, base glaze le pigment, base glaze ke phofo ea fusible glass frit;Pigment ke ntho e sa tloaelehang ea 'mala.E ka ba motsoako oa inorganic kapa metsoako e mengata ea tlhaho.E entsoe ka ho sila, ho kopanya, ho sila le ho sila ka phofo ka tekanyo e itseng.

(1) Glaze ea Motheo

Karolo ea glaze ea motheo ke ho hasanya pigment e sa tloaelehang haholo, 'me e qhibilihe holim'a karolo ea khalase ka mocheso o tlaase,' me substrate e kopantsoe ka ho feletseng;Ha "base glaze" e kopantsoe, 'mala oa inorganic o nang le bokhoni bo matla ba 'mala o tla o daea ka khalase ea' mala, 'me karolo ea khalase le khalase e kopantsoe ka botlalo' me e be khalase e mebala-bala.Ts'ebetso ea tekheniki ea glaze ea motheo e hlokahala: mocheso o qhibilihang o tlase, o ka qhibilihang holim'a karolo ea khalase pele o nolofatsa;E na le botsitso bo botle ba lik'hemik'hale le ho benya, 'me ha e hlahise tšebelisano ea lik'hemik'hale le inorganic pigment, ebile ha e etse hore' mala oa inorganic pigment ka boeona o fetohe;Coefficient ea ho atolosa e haufi haholo le coefficient ea ho atolosa ea substrate ea khalase.Ha mocheso o fetoha, glaze ha e phunye le ho chesa.

(2) Pigment

Pigment, ke mofuta oa metal oxides kapa metsoako, e ka boela ea etsoa ke li-oxide tse 'maloa tsa tšepe kapa metsoako, ho latela karo-karolelano e itseng ea ho sila, ho kopanya, ho sila, ho hlatsoa, ho sefa, ho omisa le ho sila hore e be phofo e ntle.Mebala e fapaneng ea pigment, khetho ea oxide ea tšepe, ha e nolofalloe, mocheso oa sintering le nako ea sintering e fapane le pigment.Phatlalatso ea pigment e sebelisoang e na le kamano e haufi le boholo ba eona, karoloana e nyane, ho hasana ho hoholo (karolo e ka tlase ho 5 um).

Enamelling

1. Mokhoa oa ho roala oa ho roala mokhoa oa ho roala ke molao-motheo oa ho fetisa theknoloji ea khatiso ea moqolo, glaze e teteaneng e mebala e koahetsoe holim'a karolo ea khalase e sebelisa rolara ea rabara.

2. Mokhoa oa khatiso oa skrine Mokhoa ke ho fetisetsa theknoloji ea khatiso ea skrine le theknoloji ea morao-rao ea masela, tšebeliso ea mochine oa khatiso oa skrine, glaze slurry, e koahetsoeng holim'a khalase ea khalase ea mofuta o le mong kapa ho feta oa glaze.Wire mesh e entsoe ka fiber ea maiketsetso kapa terata ea tšepe e sa hloekang.

3. Mokhoa oa ho hatakela Mokhoa ona o sebelisa thepa e bonolo e tenyetsehang e betliloeng sebakeng sa setšoantšo sa tiiso, tiiso e nang le lera la peista e mebala-bala, ebe e hatisoa holim'a substrate e hloekileng ea khalase.

4. Mokhoa oa setikara ke katoloso le katoloso ea mokhoa oa ho hatisa skrineng.Ke ho hatisa lipaterone tse rarahaneng tsa mebala e fapaneng tlase ho noka pampiring e khethehileng.Ha a sebelisoa, metsi a sebelisoa e le sekontiri, 'me a kenngoa holim'a karoloana e hloekileng ea khalase, e omisitsoeng ebe e futhumatsoa.

Omme

Ka mor'a ho qhoqhoa, lera la glaze le tlameha ho omisoa bakeng sa mohato o latelang.Ho ea ka ts'ebetso ea glazing le tekanyo ea tlhahiso, ho omisa ka tlhaho, ho omisa ka kamoreng ea motlakase le ho omisa ka mokhoa o tsoelang pele oa motlakase ho ka khethoa e le mokhoa oa ho omisa.

Ho futhumatsa le ho pholisa

Khalase enamelled e lekanang le ho futhumatsa le ho pholisa ho latela mekhoa e fapaneng ea tlhahiso, mokhoa o khethiloeng le lisebelisoa:

1.Mokhoa oa ho toughening

Mokhoa oa ho toughening ke ho fetisetsa lakane e omeletseng ea khalase ka har'a sebōpi se thata ebe o e futhumatsa ho 670 ~ 715 ℃, ebe o e fetisetsa ka potlako sebakeng sa moea bakeng sa ho tima.

2.Semi-tempering mokhoa

Mokhoa oa semi-tempering Mokhoa oa mokhoa ona ke ho fetisetsa lakane e omeletseng ea khalase ka har'a sebōpi se futhumatsang ebe o e futhumatsa mocheso o itseng, ebe o e isa ka phaposing e pholisang bakeng sa ho pholisa ho laoloang.Heating annealing method Ke letlapa le ommeng la khalase ka mor'a hore le khanye ka har'a kamore ea ho futhumatsa ea tafole e tsoelang pele, ka sebōping ka mor'a ho futhumatsa, ho futhumatsa, ho futhumatsa, ho pholile le ho etsoa ka khalase e khanyang.Mocheso o phahameng ka ho fetisisa ka sebōping ke 670 ~ 715 ℃, 'me joale annealing le pholileng li etsoa ho latela puso e itseng ea mocheso.

Molemo

1.Mechanical thepa

Ka botsitso bo botle ba lik'hemik'hale lemokgabiso, e ka etsoa ho latela litlhoko tsa mosebedisi kapa mohlala oa moralo oa bonono.

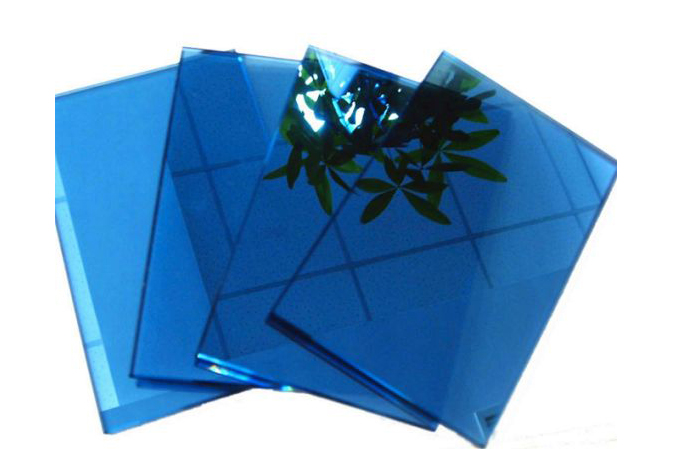

2. E matlafalitsoe aesthetic effect e ruileng 'mala

Mohlala o khabane, o se ke oa fela, o se ke oa fela, o bonolo ho o hloekisa.

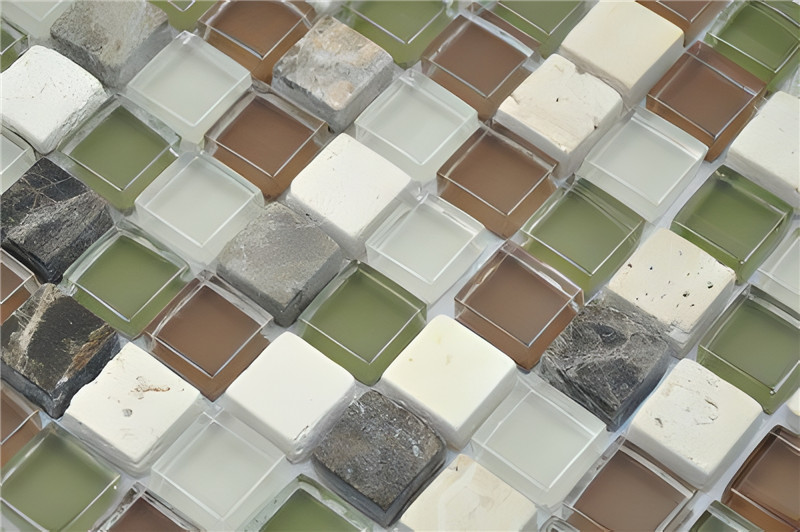

Sebaka se sebelisitsoeng

Lithako tse ka hare, liforo le litepisi tsa meaho e akaretsang le lithako tsa kantle tsa meaho;Marako a shading le spacer, li-skrini le likarolo tse ling tsa mohaho tse hlokoang ke mohaho;Lemati la onto le arolang likhalase tse bentšitsoeng, bokaholimo ba setofo, li-countertop le lisebelisoa tse phahameng tsa thepa ea ka tlung;Moriti oa lebone la khalase e khanyang, moriti oa ho fela, moriti le lisebelisoa tse ling tsa mabone;Khalase e khanyang lebone la lebone la moriti oa khalase ea koloi, joalo-joalo.

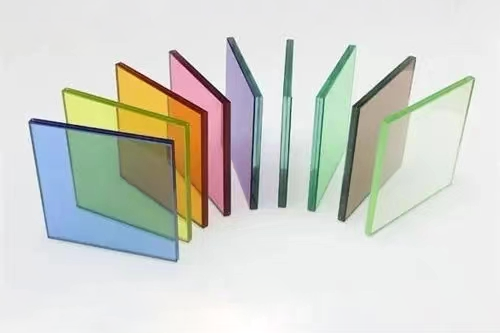

Mmala

Li-pigments tsa inorganic tse atisang ho sebelisoa bakeng sa enke ea khatiso ea khalase ke tse latelang:

1. Bofubelu -- cadmium sulfide;

2. Yellow - lead chromate, cadmium sulfide, letsoai la uranium;

3. Botala - chromium oxide;

4. Blue - cobalt aluminate;

5. Brown - iron oxide;

6. White - calcium oxide, kaolin, joalo-joalo.

7. Black - iridium oxide, manganese oxide le metsoako e meng;

Tlhahiso ea Tlhahiso

Lihlahisoa tsa k'hamphani li fetileChina e tlamang boleng ba tsamaiso ea CCC setifikeiti, Australia AS/NS2208:1996 setifikeiti, leAustralia AS/NS4666:2012 setifikeiti.Ho phaella ho finyella litekanyetso tsa tlhahiso ea naha, empa hape ho kopana le litlhoko tsa boleng ba 'maraka oa mose ho maoatle.